Welcome to the World of 3D Printing

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects directly from digital models by building them layer by layer. Unlike traditional subtractive manufacturing methods, where material is removed from a solid block, 3D printing adds material only where needed, making it highly efficient, customizable, and sustainable.

This technology enables individuals, startups, and industries to prototype, test, and produce functional parts faster and more affordably than ever before.

The History of 3D Printing

The concept of 3D printing has been around since the 1980s, but its growth over the past two decades has been exponential.

1980s–1990s: Invention & patents

The foundations of 3D printing were laid with early patents for additive manufacturing. In 1984, Chuck Hull invented stereolithography (SLA), marking the birth of modern 3D printing. The 1990s saw the introduction of Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS), pushing 3D printing into industrial applications for rapid prototyping and functional parts.

2000s: Open-source revolution

The open-source RepRap project democratized access to 3D printing, enabling hobbyists and educators to experiment with the technology.

2010s–Today: Consumer & industrial expansion

Rapid expansion in desktop 3D printers, accessibility, materials, and use cases across industries such as healthcare, fashion, education, and aerospace.

Types of 3D Printing Technologies

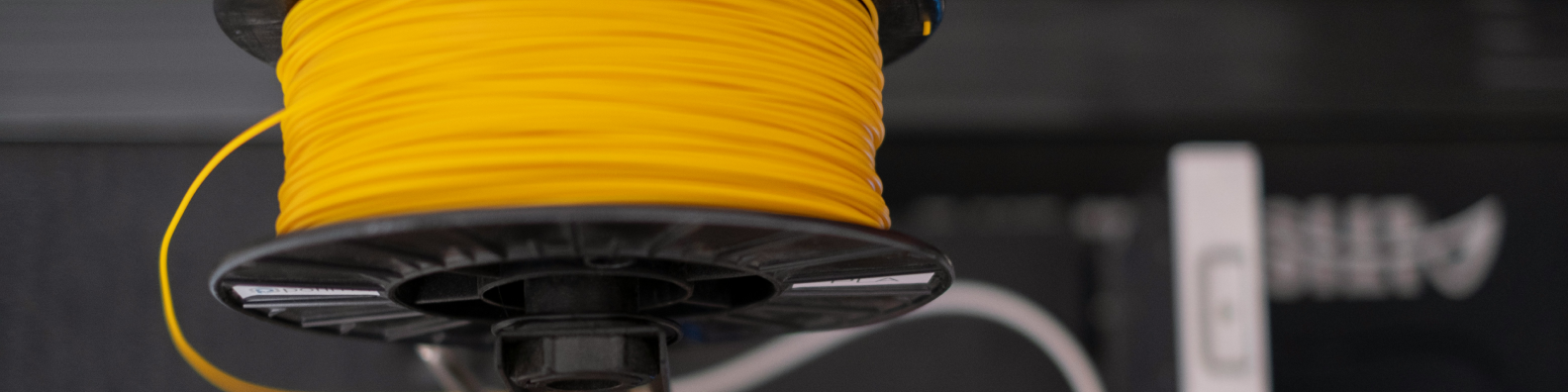

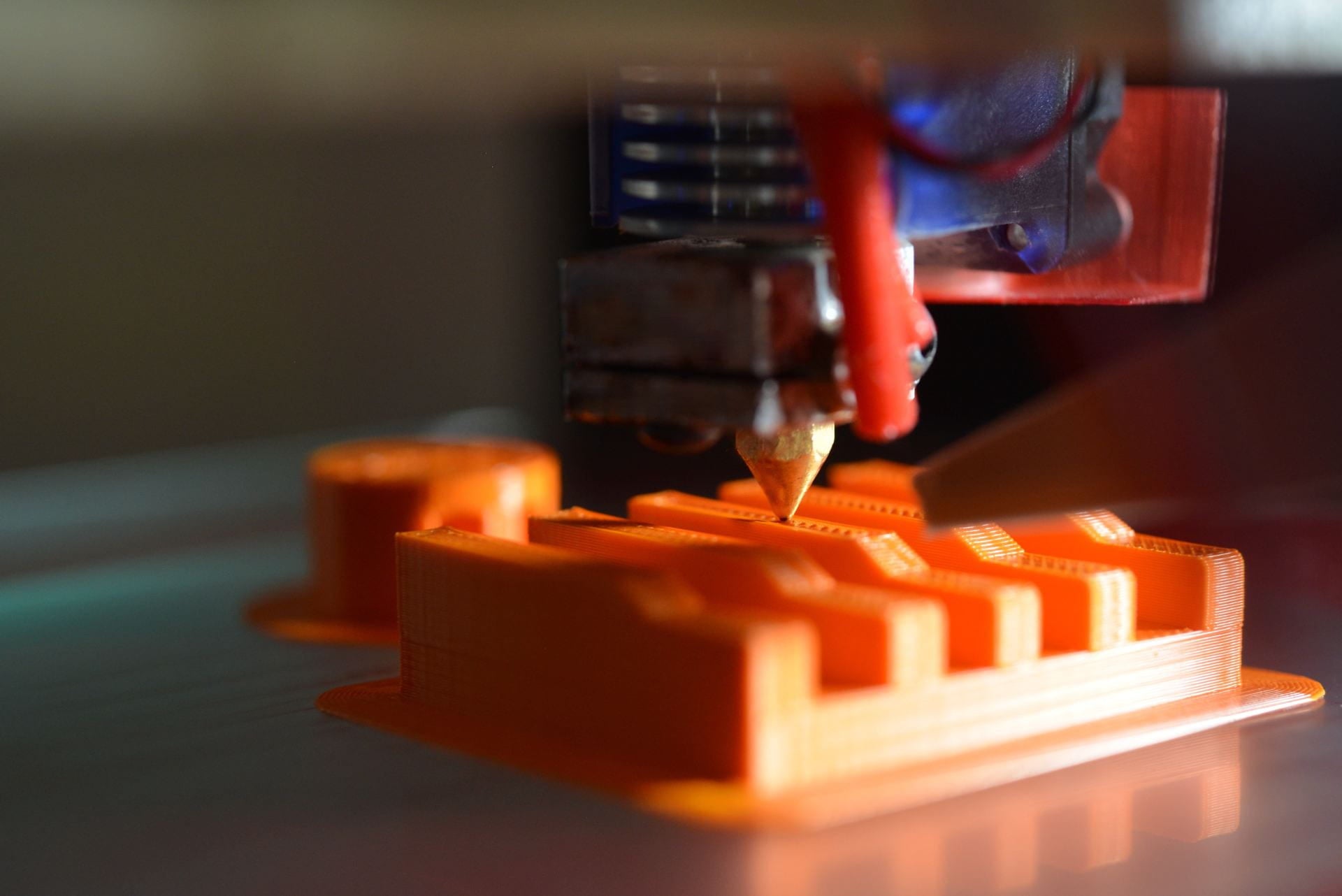

FDM (Fused Deposition Modeling)

FDM is the most widely used 3D printing technology. It involves heating and extruding thermoplastic filament through a nozzle and depositing it layer-by-layer to form the object.

- Best suited for: Prototyping, mechanical parts, desk accessories, low-cost models

- Advantages: Affordable, widely available, beginner-friendly

- Limitations: Visible layer lines, limited resolution, support structures often required

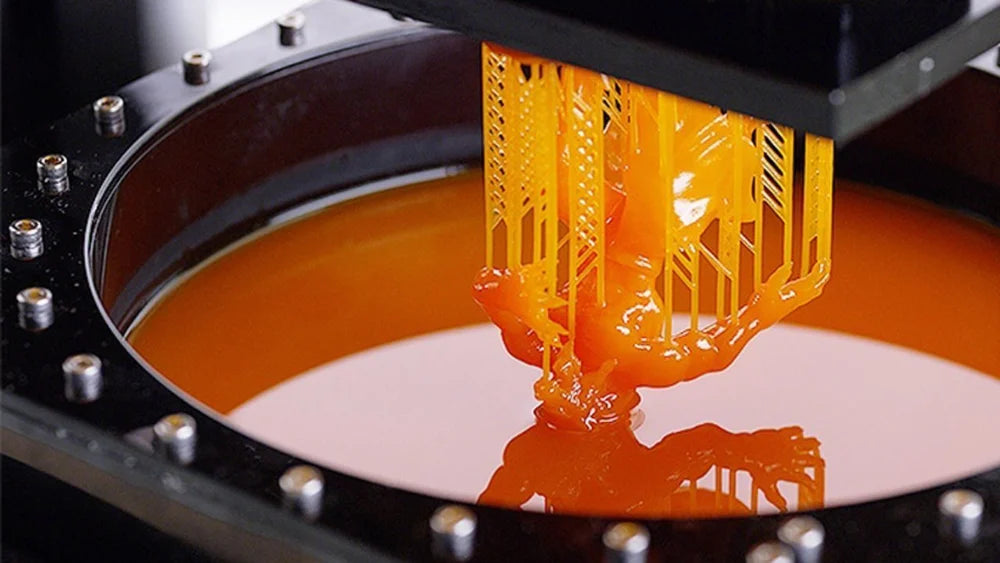

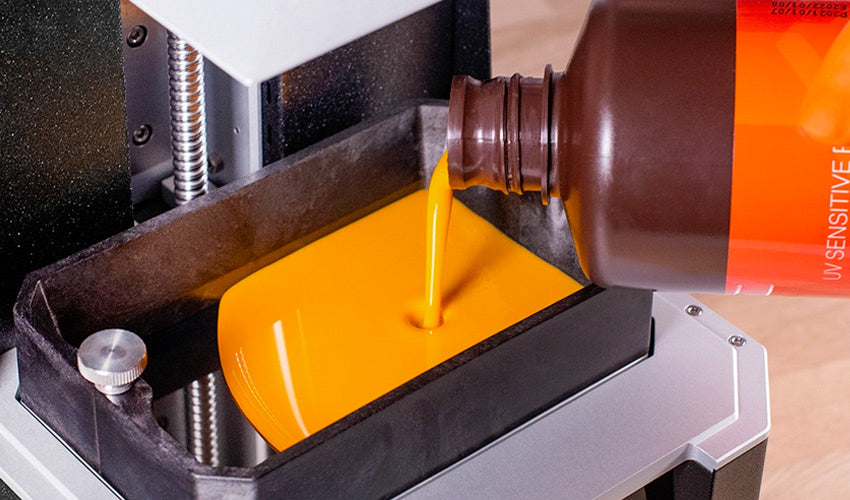

SLA (Stereolithography)

SLA uses a UV laser to cure liquid resin in a vat, layer-by-layer, producing highly detailed and smooth-surfaced parts.

- Best suited for: Jewelry, dental models, figurines, detailed prototypes

- Advantages: High resolution and accuracy, smooth finish

- Limitations: Resins can be brittle; post-processing (cleaning and curing) required

SLS (Selective Laser Sintering)

SLS uses a laser to fuse powdered material, usually nylon, into solid parts. It does not require support structures and is suitable for functional parts.

- Best suited for: Engineering parts, mechanical assemblies, batch production

- Advantages: Durable parts, no supports needed

- Limitations: Expensive, requires industrial-grade machinery

Other Technologies:

- DLP (Digital Light Processing) – Similar to SLA, but uses a projector instead of a laser

- MJF (Multi Jet Fusion) – HP’s proprietary method for high-speed, high-volume nylon printing

- Binder Jetting – Used for sand, ceramics, and metal parts

- EBM (Electron Beam Melting) – Used for titanium parts in aerospace and medical sectors

Materials Used in 3D Printing

Thermoplastics (FDM)

- PLA (Polylactic Acid) – Biodegradable, easy to print, low warp

- ABS (Acrylonitrile Butadiene Styrene) – Durable, impact-resistant, used in automotive

- PETG (Polyethylene Terephthalate Glycol) – Water-resistant, strong, chemical-resistant

- TPU (Thermoplastic Polyurethane) – Flexible, rubber-like, shock absorbing

Resins (SLA/DLP)

- Standard Resin – Smooth surface, good detail

- Tough/Durable Resin – Engineering-grade, impact-resistant

- Flexible Resin – Rubber-like properties for specialized parts

- Castable Resin – For investment casting in jewelry and dentistry

Powders (SLS, MJF, Binder Jetting)

- Nylon (PA12, PA11) – Lightweight, strong, versatile

- Metal Powders – Steel, titanium, aluminum for industrial-grade parts

- Ceramics/Sand – For artistic or structural elements

Use Cases & Applications

3D printing has a wide range of applications across industries:

Engineering & Product Development

- Rapid prototyping

- Custom jigs and fixtures

- Functional testing and design validation

Healthcare

- Dental aligners, prosthetics, anatomical models

- Surgical planning tools

- Bioprinting (research stage)

Education & Research

- STEM education tools

- Architectural and scientific modeling

- Research prototyping

Consumer Products

- Customized tools, accessories, jewelry

- Home décor, planters, phone stands

- Personalized gifts

Manufacturing

- Low-volume production

- On-demand spare parts

- Mass customization